Beauty and personal care products operate under a highly competitive space where time to market literally equals market share. By using a lotion bottle filler you can multiply your production, exponentially. Well, today, we are about to examine the tangible benefits and the consequential difference a lotion bottle filler can make for your business.

Efficient production process

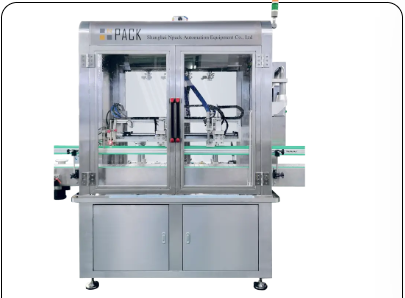

By automating the filling stage of packaging, using a lotion bottle filler makes the whole process of packaging that much more efficient than manual methods. This manual filling process is not only slow, but it can also be inaccurate, which can lead to slower production rates and a lower standard of product. At the other end of the spectrum, automatic fillers can process 20 to 120 bottles per minute, making them vastly more efficient than more intervention-based manual processing.

Precision and Consistency

An automated lotion bottle filler will allow you to accurately put the same amount of product in each bottle so that you reduce waste and maintain consistency. The brand can retain its reputation only by ensuring this consistency, because every single product a buyer pays for is expected to embody the quality of the last purchase he made.

Scaling for small-mediumExpansion Friendly

The possibility to scale horizontally is a very important quality as businesses grow. These fillers, being in the category of a lotion bottle filler, are easy to the bottle size and type and can be adapted in a short change-over to keep up with sudden changes in the production volume without adding up to downtime on the line. This flexibility is key as it allows organizations to quickly react to changes in the way markets or potential customers can be approached.

Cost Efficiency

Even though the initial cost of a lotion bottle filler may be high, the more production and the savings in labor costs it creates can give you quick return on investment. Moreover, by reducing product loss during the filling, this is tens, sometimes even hundreds of thousands of dollars a year.

Enhanced Product Safety

Automated fillers also help that the beauty and personal care materials are less likely to be contaminated since human touching and human-related activities are minimized during the filling process. Proof Systems: Proof filling systems are implemented everywhere the regulations require, so that filling happens in a controlled environment.It helps in keeping the appropriate certification and helps in building consumer trust.

A purchase of a lotion bottle filler is an investment in the future expansion of your enterprise. Technology has become an absolute must-have upgrade for any business aiming to grow in a constantly shifting industry, and this one, with its enhanced efficiency and consistency, combined with the ability to grow rapidly with you, provides the ideal approach.